Table of Contents: What Size PVC for Sprinklers Do You Need?

Calculating the Correct Pipe Size

Sprinkler pipe size can directly affect water flow, pressure, and the overall efficiency of the system. If the pipe is too small, it creates more friction as water moves through, messing up your water pressure and causing uneven coverage. On the other hand, if the pipe is too large, it can be unnecessarily expensive without adding much benefit to a smaller system. As such, it’s important to consider sprinkler pipe diameter when building your irrigation system. If you already have some pipe, click here to learn how to determine what kind of pipe it is.

As a rule of thumb, when deciding what size PVC to use for your sprinklers, do not use a smaller pipe diameter than is recommended. In certain instances, sizing up can help to compensate for low pressure and or for very long pipe runs, but for smaller systems, try to stick to the recommended irrigation pipe size.

PVC, or polyvinyl chloride, is one of the most popular types of sprinkler pipe on the market. This type of pipe accounts for about two-thirds of the water distribution market, including drinking, irrigation, and waste. Unlike metal, PVC won’t rust or corrode. The material is also inert, meaning it doesn’t absorb or release harmful chemicals. The smoke from burning PVC can be hazardous, but we’re working with water, not fire!

But PVC comes in many different shapes and sizes, and it may not be obvious which is appropriate for your setup. The most common question we get is a two-parter: what size pipe should I use, and what kind: Schedule 40 or Class 200? Knowing the differences can help you create an efficient system.

Schedule 40 Pipe

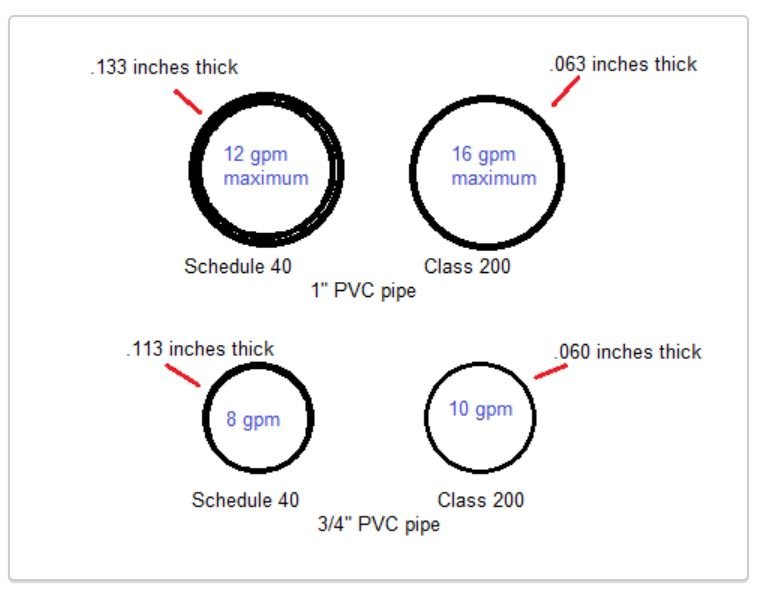

In PVC (and also in metal piping), “schedule” is used to describe how thick the pipe walls are for a given diameter, with a higher schedule indicating thicker walls. For example, a 1” pipe in schedule 40 has a wall thickness of .133” while schedule 80 has a wall thickness of .179”. Schedule 40 PVC pipe is a common irrigation pipe size with medium thickness and can handle moderate pressure. This type of pipe is pretty standard in irrigation. It’s strong enough for most residential and light commercial uses without being too heavy or expensive.

Class 200 Pipe

“Class” pipe refers to PVC pipe that’s rated by its working pressure instead of the thickness of its walls. Class 200 pipe, the most common class pipe used in irrigation, is rated for 200 pounds per square inch pressure (psi) and has a wall thickness of .063” for a 1” pipe. The wall thickness of Class pipe changes with the diameter to meet that pressure rating, so it’s not uniform like in Schedule pipe.

Irrigation System Design

Most irrigation systems are designed to run at 30 to 50 PSI during normal operation. Plus, as an added safety factor, the pipe, fittings, and components can usually handle more pressure than the system’s normal operating pressure. In a poorly designed system, sudden changes in water flow can cause water hammer, which is a shockwave in the pipe that briefly spikes pressure far above normal. For example, a pipe rated for 60 PSI might momentarily see spikes up to 170 PSI. That might still be within the pipe’s rated burst strength, so it probably won’t explode, but those surges can shorten the lifespan of the system if they happen too often.

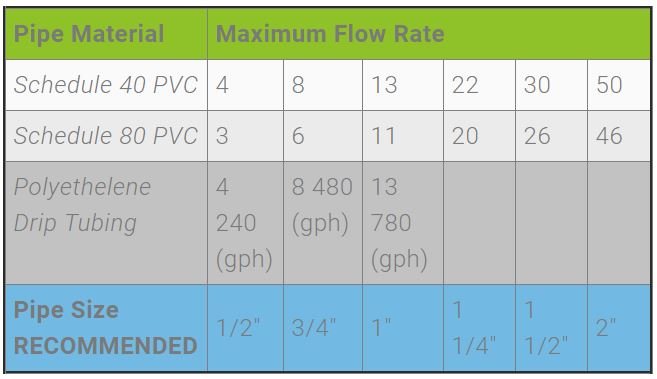

Now we can get into the “why do we care” part. Everything in irrigation ties into gallons per minute. Each sprinkler head uses a set amount of water per minute, and your water supply can only deliver so much before pressure drops. For example, if your system can supply 13 GPM, you could run six heads that use 2 GPM each, or four heads at 2 GPM plus four heads at 1 GPM. (Never design to the absolute max gpm.)

As you’ll see in our sprinkler pipe size chart (above), pipes with the same diameter will have different flow capacities depending on whether it’s Schedule 40 or Class 200. This is because the pipe’s thickness and the size of the inside diameter can directly affect how easily water moves through the pipe.

Which Sprinkler Pipe Diameter Do You Choose?

Schedule 40 and Class 200 are both common sprinkler pipe sizes, but which is best for your irrigation system? The answer mainly comes down to pressure rating and costs. Class 200 is less expensive and has thinner walls, which means it’s lighter while still being strong enough for most irrigation systems (typically 30–80 PSI). While it is more expensive, Schedule 40 has thicker walls and higher burst strength, making it better for higher-pressure applications or areas where water hammer might be more severe.

An easy rule of thumb is to use schedule 40 for the main line. Run it from the water meter, through the backflow, and to the valves, then use class 200 for the laterals, or after the valves.

Why Schedule 40 When It Allows Fewer Gallons Per Minute?

Schedule 40 pipe is often chosen for its thicker walls, which make it stronger and more resistant to physical damage. Even though the thicker walls slightly reduce how much water it can carry, the added defense is sometimes necessary. The main line in an irrigation system is always pressurized, while lateral lines only have pressure when that zone is running. As such, using Schedule 40 pipe kind of just makes sense for the main line.

But, there are exceptions to everything. There are situations where an entire system should be done in class 200 pipes. Same for schedule 40.

The chart above answers the question about how to determine what size you need. Begin by finding the pipe material you have chosen, as well as the flow rate that you have calculated. The bottom of the chart shows the results for the recommended pipe size.

Choosing the right sprinkler pipe size is crucial when building an efficient irrigation system. By understanding the differences between Schedule 40 and Class 200 PVC pipe, you can shop for the right balance of durability and flow capacity that suits your system. Just remember to keep your system within the recommended pressure and flow rates, and you’ll be able to maximize the lifespan and effectiveness of your irrigation setup.