This article covers the identification of various types of irrigation valves and covers some of the key terms involved.

Lawn Irrigation Systems Are Classified As “Inline” Or “Anti-Siphon.”

In an inline system, valves are in line with the underground supply pipe or tubing. Inline valves control or block flow by means of a mechanical obstruction activated manually or electronically. You can install inline valves just about anywhere in the landscape without creating a visual nuisance.

In an anti-siphon system, valves are above ground. They sit on a supply line that loops up out of the ground in an inconspicuous location. Anti-siphon valves work by imposing an air gap to prevent siphonage whenever a backflow condition is present. Above-grade installation precludes the danger of submersion and provides more convenient access for maintenance and repair.

Lawn Sprinkler System Valves Categorized By Use:

Isolation Valve:

Isolates the irrigation system from the main water supply when closed. When this valve is open, water from the main supply line enters the irrigation system. The isolation valve closes for winterization. In an in-line irrigation system, this valve is usually located underground near the meter. In an above-ground system, it is usually located indoors or above ground near the point where the main water line exits a structure (usually a basement or garage).

Backflow Prevention Device:

A valve or valves in a configuration for the purpose of preventing water that has entered the irrigation system from flowing back into the potable water system. In terms of health and safety, this is the most critical component of any lawn sprinkler system. Whether above or below ground, this unit should always be downstream from the isolation valve.

Automatic Zone Control Valve:

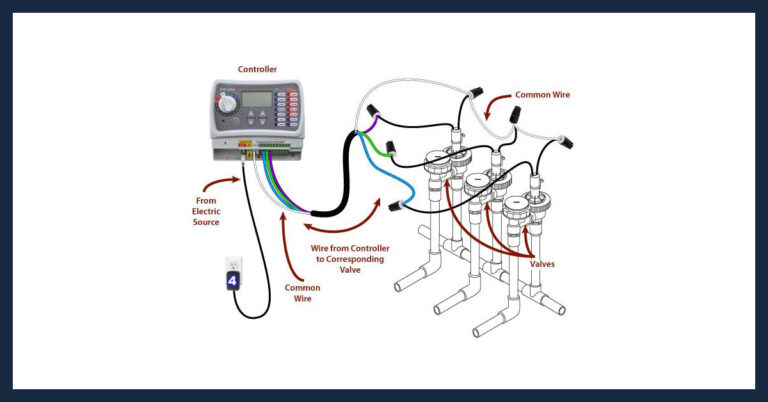

A valve is connected to a timer/controller that controls the flow of water to a zone of sprinkler heads and drip emitters. Inline zone control valves are installed in a valve box below grade. Anti-siphon control valves are installed above ground in an inconspicuous location.

Lateral Line Drain Valve:

A simple valve is installed at the downstream ends and low spots in a system to drain lateral lines after each use.

Lawn Sprinkler System Valves: Identification

Valves are identified by their size, inlet connection type, outlet connection type (if different), and mechanism. (Example: 1″ NPT ball valve).

Mechanism Types Include:

Ball Valve:

Opens, when a sphere with one hole bored through the center, aligns with the inlet and closes when the quarter-turn handle turns the ball and the hole perpendicular to the inlet.

Gate Valve:

Is OPEN when a disk-shaped “gate” is drawn up out of the water pathway and CLOSED when the handle is rotated clockwise several times lowering the gate into the pathway.

Check Valve:

A disk is seated on a seal at a forty-five-degree angle to horizontal. Water flowing in the normal direction pushes the disk upward allowing flow. Water backflowing pushes the disk down against the seat stopping the flow.

Automatic Valve:

A solenoid opens the valve automatically at times and intervals programmed into the system controller.

Connection Types Commonly Found On Inline Underground Irrigation System Valves Include:

FPT:

Female Threaded. Also sometimes called FIP

MPT:

Male Threaded. Also sometimes called MIP.

NPT:

National Pipe Thread.

S (or Slip):

Straight, smooth female connector receives pipe or “street” (male) fitting. Metal slip connections are soldered or brazed (a.k.a. sweating); plastic connections are glued.

Barb:

Male connector with barbs slips inside pipe or tubing. Use stainless steel crimp clamps to hold them in place. (Not used for BPD)

Union:

A two-piece threaded connector is usually installed in pairs so that whatever is between them can easily be disconnected. When installing these, you glue the inlet and outlet of each union to the pipe or valve. By tightening the nut on one piece to the threaded portion of the other piece you complete the connection.

Miscellaneous Terms:

PVC:

An abbreviated form of the term Schedule-40 PVC pipe. You can often use Lighter PVC for supply lines downstream of the zone control valves. But for the valve installations explained here, PVC means Schedule-40.

Solenoid:

An electromagnetic device consisting of wire wrapped around a core that produces a magnetic field when activated. In irrigation applications, it opens automatic lawn sprinkler system valves when activated by the system controller.

Glue:

A commonly used misnomer for solvent cement. To “glue” a plastic joint means to use either one-step “green” solvent cement or primer and regular solvent cement. The solvent cement looks and spreads like glue but reacts chemically with the plastic causing it to soften or melt slightly so a hub and pipe meld together.

Thread Tape:

Is a very thin non-adhesive tape for making threaded connections. It provides a very satisfactory waterproof seal for tapered-thread joints when applied correctly. The Teflon reduces friction so that the threads can be made up tightly, and then it fills tiny gaps by expansion.

Half-inch width works best for most lawn irrigation applications. Wrap the tape clockwise beginning one-half the width of the tape from the end of the male threads. On the first wrap, wrap down to the end of the threads, then begin wrapping upward to cover the loose end. Keep the tape flat. Don’t allow the tape to extend off the threads at the end of the pipe. Keep just enough tension on the tape while wrapping to cause the tape to stretch tightly into the threads without breaking.

Overlap each wrap by fifty percent. Add a final wrap at the top of the threads directly over the previous wrap, and then hold the tape tightly against the threads with one finger while pulling to break the tape. Well-taped threads look almost like you painted them white.

Thread Sealant Compound:

Is easier to apply and more forgiving than Teflon tape. Look for a brand impregnated with Teflon for the best friction reduction. Thread sealant compound works well with brass, copper, and PVC, but any excess that squeezes into the pipe or fitting should be removed by hand. Do not depend on flushing the system to get rid of the excess. Compounds can clog valves if left in the pipe. The solvents in the thread sealant compound can damage other types of plastic. Use the tape when either part of the connection is polybutylene, ABS, or any plastic other than PVC.