(Transcribed from the video above)

Protect Your Backflow Device From Freeze Damage

Hi, Alfred Castillo here, your Sprinkler Warehouse Pro. Today I’m going to share with you how to actually winterize a backflow preventer and protect your PVB with foam pipe insulation.

In its current state, you can see that both of my valves are in the open position. So, we got supply going into the backflow preventer, out to the outlet, into the valves. So, this is normally the way your sprinkler system will operate. To protect our backflow preventer for the winter, we have to take a few extra measures here to prevent any kind of failures of this backflow as the water supply runs up into the pressure vacuum breaker.

Turn The Valves To Release Pressure From Valves And Cock Stops

We want to go ahead and turn this valve that’s currently on. You can tell they’re on when they point in the same direction as the pipe. So, if it’s parallel to the pipe—they are on. We’re gonna end up turning this particular valve, off. We want to ensure that any water that might be in this particular PVB has the opportunity to expand without breaking the valve or the cap. So, what we’re going to do is release to relieve the pressure from what we call here at these bleed valves or these cock stops.

Right now, they are in a closed position. As you can see here, they’re perpendicular to the actual valve itself. We want to go ahead and release these bleed valves. If you can, then turn them right now so that it’s closed. These ball valves are not a screw. They are just really simple ball valves that rotate. Turn one way to open and the other way to close. It’s not a screw so right now that’s closed. Again, in the winterization of this particular backflow preventer, we always want to keep them open so any expansion of water will actually flush out over here.

Wrap Backflow Preventer Pipes With Foam Pipe Insulation

The next step to make this particular winterization more effective is to go ahead and utilize insulation. I have a couple of pieces here that I’ve pre-cut just for the sake of this video. We’ll actually go ahead, and you can pick this particular installation up at Sprinkler Warehouse. So, what we’re going to end up doing is we’re going to insulate the supply side first.

Now one of the important things that we want to point out when we’re insulating the supply side is that many times, homeowners will only insulate up to the actual valve itself. Or they might wrap the foam pipe insulation up to the brass part. That’s where a lot of homeowners make mistakes. They fail to recognize that insulating this particular valve is just as critical.

Beware The Valve Can Still Hold Water When It’s Closed, Presenting A Freeze Risk

Why is that? As you can see here, on this particular valve. Water flows right in through here. Well, when it closes you can see the stainless ball valve that is in here. It opens and closes. Well, when you close this—we actually have water that is still in that ball valve, and part of that water essentially is just resting now on the sides of the valve itself. Well if we don’t properly insulate this part. You can see what might happen in the event of a hard freeze. The water will expand and you’ll get a pretty good-sized crack, and this is brass, my friends.

So, this is just what a little water can do if we don’t properly insulate. When insulating and winterizing your PVB, your backflow preventer it’s important to go ahead and wrap the foam pipe insulation all the way to the actual PVB itself.

Carefully Measure, Then Cut The Water Pipe Insulation

You’ll see here as I make the measurements. You can make cuts on the insulation. Then we’re going to go ahead and wrap foam pipe insulation all the way up to pretty much where—the PVB starts. So, we have the valve insulated and you actually also have the PVC pipe insulated. Again, our knob is in its off position here.

Sprinkler Warehouse Has Valve Knob Replacement Kits

Sometimes these knobs will rust out and go bad. We also have a kit here where you can buy these particular valves right here at the Sprinkler Warehouse. They are made of stainless steel. You don’t have to worry about rust or anything like that. Once we have this pre-cut and trimmed foam pipe insulation. Then get some tape. Now you want to go ahead and try to insulate as much of this particular valve as possible.

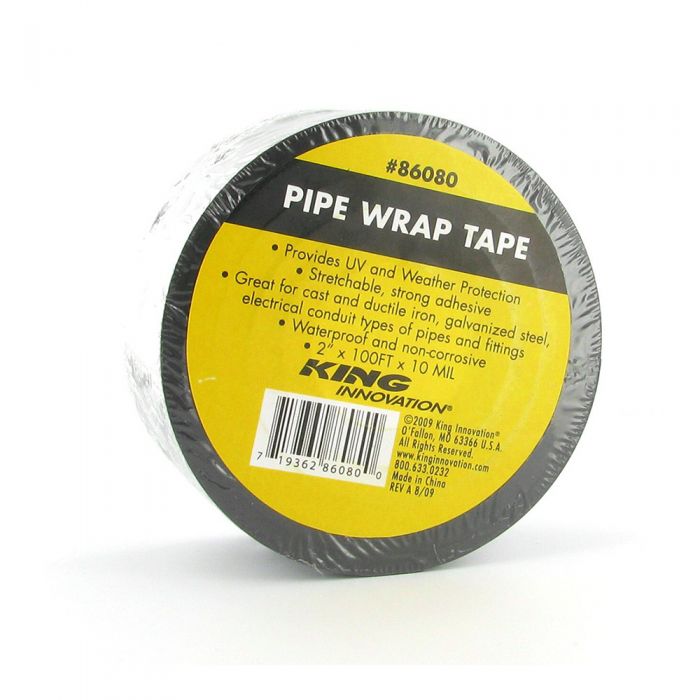

Pipe Wrap Tape Is The Best Choice For Water Pipe Insulation

Pipe Wrap Tape From King Innovation, 100 ft.

As you can see here, it’s closed pretty well. I can close that up when I tighten it up. You want to see if you can cover up any exposed part. If there’s any excess insulation here. You can go ahead and tape it up. Just measure out what you need to cut out. I’m just going to go ahead and try to fill that gap. With um—with a particular little bit of insulation. So, I can close this, and then we’ll have an effective and very nice tight fit.

Make Sure Pipe Insulation Foam Covers Every Part Of The Valve

The important thing is you want to make sure that every part of this valve is insulated. We have this particular insulation tape that you can also pick up here at Sprinkler Warehouse. Then we’ll just go ahead and start insulating. From the top. It’s important to ensure that we have a good tight fit around there. You want to wrap it around a couple of times to ensure that you don’t have any kind of exposure. Make sure you have a tight seal around it. I’m going to go ahead and wrap it around a couple of times. I’m gonna do a little overlap as well to ensure that I do have it completely covered.

Continue to wrap the pipe insulation foam around if need be. If any water is built up in this particular valve as a result of the closure, with it being properly insulated, you really don’t have to worry now about any type of rupture. So, the important thing is to insulate the supply side with foam pipe insulation. It’s also a good idea to insulate the side that will go to your valve. By doing that again you can go ahead and measure some insulation. We want to do the same thing as well. We want to not only measure the actual PVC pipe, but we want to measure the insulation to cover the actual valve itself. For very similar reasons as we’re covering the supply side valve. We want to cover the outlet valve as well.

Make Sure The Pipe Wrap Tape Covers The Foam Pipe Insulation All The Way

So, what we’ll do is go ahead and continue to wrap up this side here. Once you get the measurement you want to go ahead and go all the way to the PBV. We also want to see if we can get a good little insulation to cover every part of that valve as possible. Make sure it is completely covered.

Then I can go ahead and insulate the rest of the pipe. While accommodating it, I might have to just snake it in a little bit here to make sure that I got a good wrap. I’ll wrap it around then I’ll just continue wrapping the rest of this particular pipe. I’ll wrap this side some more as needed. You can go ahead and finish that off to properly insulating it.

So, there you have it, my friends. Now you have the proper winterization technique of a backflow preventer. We covered how to make this winterized with the proper positions on your valves, and your actual valves which are supposed to be closed. We have now completed the proper way to insulate a backflow preventer.

Feel free to leave a comment. Let us know what other subjects you are interested in learning about. So, again Alfred Castillo here from Sprinkler Warehouse.

Check out our YouTube channel to learn more about irrigation and sprinkler system maintenance.