Overview Of Four Common Backflow Preventers

What Each One Does and How It Works For You

There are multiple types of backflow preventers. The three most common are the pressure vacuum breaker (PVB), the reduced pressure zone (RPZ), and the double check assembly (DCA). These are all installed in the water system immediately after the isolation valve. There is a fourth backflow preventer which is also fairly common. The atmospheric vacuum breaker (AVB) is installed in each zone of the sprinkler system. After that, it immediately follows the zone control valve. Each type of backflow device is designed to provide a different level of protection for varying commercial or residential applications. For example, hospitals and morgues, which handle large quantities of hazardous wastes on a daily basis, require much heavier-duty backflow preventers than a residential irrigation system.

Several factors must be taken into consideration when selecting a backflow device. These include local building codes regulating backflow preventers, the size of the landscape to be irrigated, and where the backflow preventer is going to be installed. It’s a good idea to familiarize yourself with the different types of backflow devices. It will help you to select the one that best meets your requirements.

The first Type Of Backflow Preventer Is The Pressure Vacuum Breaker

Pressure vacuum breaker assemblies (PVB) are the most common, inexpensive type of whole-system backflow preventer. It consists of an inlet shutoff valve at the bottom, a single valve body consisting of a pressure vacuum breaker, a check valve, two test cocks, and an outlet shutoff valve. As well as being inexpensive, PVBs are relatively simple in design and are easy to install, maintain and repair. Some pressure vacuum breakers also offer built-in freeze protection; however, this only protects the PVB assembly. Inlet and outlet pipes can still freeze if the system isn’t properly winterized.

One of the downsides of PVBs is that they will occasionally eject some water. Choose a “spill-resistant” model of PVB for indoor installations or any time spillage would create a nuisance. An air gap drain is also required if the valve is installed in a basement or other interior space.

Pressure Vacuum Breaker Assemblies:

- Installed at least twelve inches above the highest downstream point on the system

- Install vertically (with the inlet at the bottom)

- Prevents back-siphonage only, not back-pressure

- No chemigation with PVBs

- Installation not allowed where back-pressure is a potential threat

The Second Type Of Backflow Preventer Is The Double Check Valves

Double check valves (DCV, also called double check assemblies or DCA) are a good choice for underground or indoor installations. A DCA consists of an inlet shutoff valve, two independently operating spring-loaded check valves (usually inside a single valve body), four test cocks, and an outlet shutoff valve. If local building codes allow for it, you must install Double check assemblies vertically.

The DCA is the most common type of approved backflow prevention device for use in underground or in-line installations. In-line (or below-grade) simply means that the backflow device is parallel with the piping of the sprinkler system; unlike the PVB, the DCA does not have to be installed 12 inches above the highest point in the system. Some areas do require above-ground installation, so check with local authorities before installing below ground.

It is possible to build a double check valve assembly from new components, but this is not the best option as there is a high risk of built assemblies not meeting local code. A better option, for convenience, cost-effectiveness, and coding restrictions, is to purchase a pre-assembled double check valve assembly.

Double Check Valve Assemblies:

Installed either above ground or inline (underground) Do not use with chemigation May be installed horizontally or vertically, but horizontally is preferred May be installed where the potential for back-siphonage or backpressure is present.

The Third Type Of Backflow Preventer Is The Reduced Pressure Zone Assembly

Reduced pressure zone assemblies (RPZ), also sometimes called a reduced pressure principle assembly, is the most complex and expensive backflow preventer. However, when working properly, RPZs are the most secure and reliable of all backflow prevention devices. A reduced pressure zone assembly consists of an inlet shutoff valve, two independently operating spring-loaded check valves separated by a pressure differential relief valve, four test cocks, and an outlet shutoff valve.

Some localities, such as Honolulu, do not allow reduced pressure zone assemblies to be installed below grade in underground lawn sprinkler systems, while others require copper pipes on both ends of the assembly. Local codes may be especially variable and stringent on reduced pressure zone assembly, so have a thorough understanding of local requirements before proceeding.

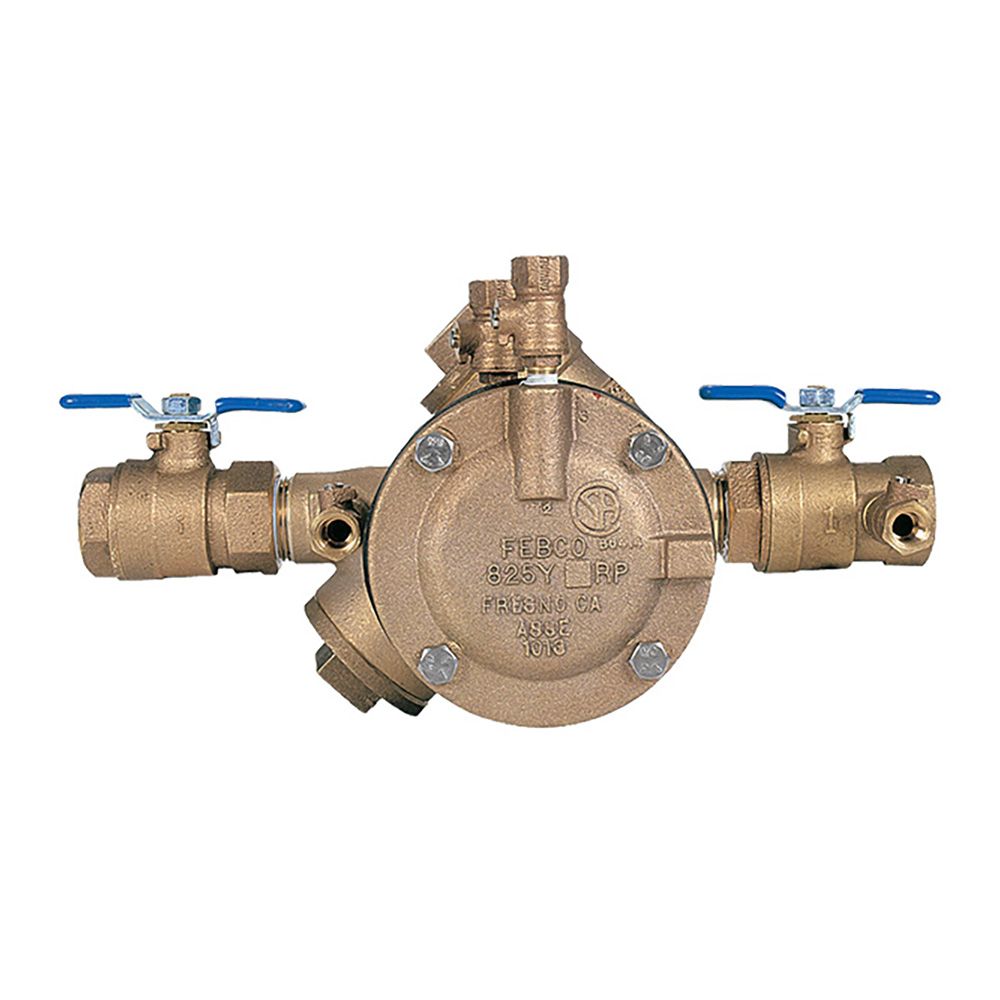

The image above shows the Febco 825Y Reduced Pressure Zone Backflow Preventer. Shop for this and other backflow preventers at SprinklerWarehouse.com.

Reduced pressure zone assemblies come in a variety of configurations. Choose an “inline” or “straight” configuration for installation underground. For above-ground installation, consider an “n” configuration assembly for a very small footprint.

Reduced Pressure Zone Assemblies:

- Compatible with both above ground or below ground installation, above ground preferred

- RPZs approve Chemigation

- Horizontal installation required unless factory-configured for alternate installation

- Protects against both beck-siphonage and back-pressure

Atmospheric Vacuum Breaker (Anti-Siphon)

Atmospheric vacuum breakers (AVB) are the simplest and least expensive backflow preventers for one or two-zone irrigation systems. An AVB must be installed on the pipe directly after every control valve, so for systems with more than about six control valves, AVBs are not cost-effective.

AVBs are also the least reliable and least often recommended. Most large cities and suburbs do not allow the use of atmospheric vacuum breakers in lawn sprinkler systems. Do not use AVBs in areas of constant pressure. This includes where shutoff valves would be located downstream where there is a potential for back pressure, or on any system that incorporates chemigation techniques.

Atmospheric Vacuum Breaker Assemblies:

- Install at least six inches above the highest outlet In the zone

- Install vertically with the bonnet on top, prevents back-siphonage only

- Requires one unit per zone installed downstream from zone control valves

- Not usable where it will be under continuous pressure for more than 12 hours at a time

- Not usable with chemigation

- May not be installed where the potential for backpressure is present