Anti-Siphon vs. Inline Valves: Here’s the Skinny

Table of Contents

So many valves to choose from! If you don’t know much about sprinkler valves, it’s easy to get overwhelmed. So today we’re going to walk through some valves and help you figure out what you need.

Two of the most common types of control valves are anti-siphon valves and inline valves. While both types serve the essential function of controlling water flow to different zones, they operate differently and are suited to different situations. Choosing the wrong type can lead to poor water distribution, potential backflow issues, or even violations of local codes.

What Is an Anti-Siphon Valve?

An anti-siphon valve is a control valve that’s designed to prevent contaminated water from flowing backward into your main water supply. It achieves this by automatically breaking the siphon when water stops flowing, protecting both your plumbing system and water quality.

By combining the functions of a regular control valve with a built-in backflow prevention mechanism, anti-siphon valves often eliminate the need for a separate backflow device. They are usually easy to install, maintain, and replace, which makes them popular for smaller irrigation zones. However, one key feature to keep in mind is their height requirement. Anti-siphon valves must be installed higher than the highest sprinkler or emitter in the system to function correctly.

These sprinkler valves are ideal for systems where backflow prevention is required by code or recommended for safety, such as near chemical fertilizers or potable water sources.

What Is an Inline Valve?

An inline valve is a type of irrigation valve installed directly along the irrigation line, usually below ground or within a valve box. Unlike anti-siphon valves, inline valves do not have built-in backflow prevention, so they rely on separate devices or system design to protect the main water supply. Their primary function is to control water flow to different zones of your irrigation system, turning sprinklers or drip lines on and off as needed.

Inline valves are commonly used in larger irrigation systems or areas where multiple valves are grouped together. Inline valves are compact, but can usually handle higher pressures and flow rates in bigger systems. While inline valves are generally pretty cost-effective, pairing them with a separate backflow prevention device is critical to protect your potable water supply, and is often required by code.

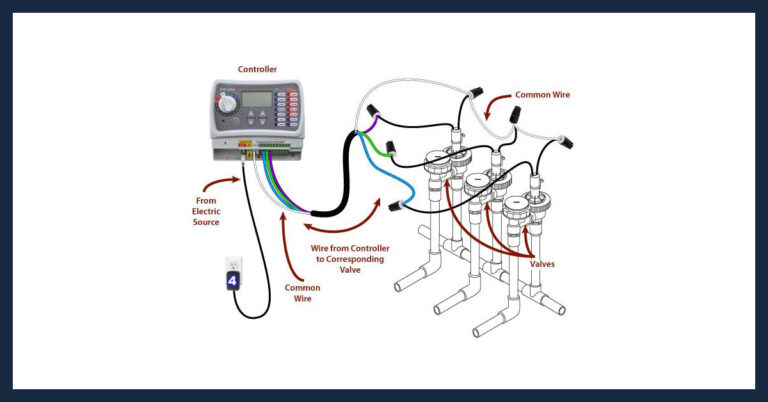

Installation

The installation process for anti-siphon valves and inline valves differs mainly in their location and plumbing requirements.

Anti-siphon combines both flow control and backflow protection in one unit, so they typically connect directly to the water supply line with minimal additional equipment. However, as a reminder, anti-siphon valves must be installed above ground and positioned at least six inches higher than the highest sprinkler head or emitter in the system. This elevation allows the built-in backflow mechanism to work properly.

Inline valves, on the other hand, are installed underground, usually within a valve box for protection and easy access. Inline valves are connected directly to the main irrigation line, making them less visible and more suitable for larger or more complex systems. However, inline valves require a separate backflow prevention device installed upstream to meet local safety requirements.

Environmental Considerations

Anti-siphon valves, because they are installed above ground, are more exposed to temperature changes. In hot, sunny climates, UV exposure can cause the plastic housing to deteriorate faster if not properly shielded. In cold regions, above-ground installations are more prone to freezing, which can lead to cracking or leaks if the system isn’t winterized correctly. However, their elevated position makes inspection and maintenance easier, which can help extend their lifespan in moderate climates.

Inline valves are installed underground and are naturally shielded from the sun and the snow. This makes them better suited for areas with harsh weather. Still, even though their buried installation helps prevent damage from the elements, it also makes leaks harder to spot, so be sure to check up on them a few times each watering season.

Complying with Local Codes

Local plumbing and irrigation codes often dictate which type of valve you can use and how it needs to be installed. Anti-siphon valves are typically required where backflow prevention is necessary, especially when the irrigation system is connected to a potable water supply. Many municipalities will even check that these valves are installed above ground and at a specific height to ensure they function properly. Inline valves will also require a separate backflow prevention device to meet code.

Cost Comparison

When comparing costs, anti-siphon valves are generally more affordable in the long run, as you won’t need to purchase a separate backflow preventer along with your valve. For example, most of the anti-siphon valves available at Sprinkler Warehouse are generally around $20 to $30, with a few higher-end models over $100. Inline valves, on the other hand, tend to be less expensive individually but require a separate backflow prevention device, which adds to the total installation cost. However, for larger systems, inline valves can be more economical in the long run due to their scalability. At Sprinkler Warehouse, there are plenty of valves starting at $15, as well as some advanced models that cost several hundred dollars each.

Choosing a Valve

Choosing between an anti-siphon valve and an inline valve will ultimately come down to how your system is set up. Anti-siphon valves are ideal for smaller, above-ground systems where built-in backflow protection simplifies installation. Inline valves, while requiring separate backflow prevention, are better suited for larger or underground systems where durability and flexibility are key.

FAQs

Can I use an anti-siphon valve underground?

No. One of the key differentiators between anti-siphon valves and inline valves is how they need to be installed, and anti-siphon valves need to be installed above ground. Anti-siphon valves must be installed above the highest sprinkler or emitter, or the backflow preventer will not operate properly.

Can I use anti-siphon and inline valves in one system

You can use both anti-siphon and inline valves in the same sprinkler system, but you would typically use the two types of valves for different zones or different parts of the system. Using both in the same water line is less common. Ensure that the entire system is protected from backflow and make sure that it adheres to local codes.

Which valve is better for cold climates?

In areas that are prone to freezing, inline valves are generally the safer choice. Neither valve is “freeze-proof,” but their installation methods determine their vulnerability. Inline valves are typically installed underground, away from the snow and ice, while anti-siphon valves are above ground and more exposed to freezing temperatures.